Cut and drill the glass

Post from EditorialsCutting the glass is a delicate operation, however, it can also be performed independently with great accuracy if you use the right tools.

Cutting and drilling glass

Cut and drill the glass is a work that is often thought reserved to technicians with special skills. It is, however, a very simple task to accomplish, if you do not forget the fragility of the material to be treated and then you act with caution. Acquiring these techniques, you can repair by yourself windows, fans and enforce the implementation of many other interventions.

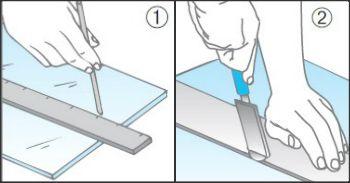

1) Mark the cutting line with a vetrographic pencil and a metal ruler.

2) With the glass cutter wheel performed in a continuous movement along the cutting line, by exerting a certain pressure. Help yourself with the metal ruler.

3) Place the plate on a wooden strip overlaying the cutting line to its axis. So press the edges to produce the fracture

4) If along the line of fracture come out smudges, delete them with a carborundum stone, with high abrasive power.

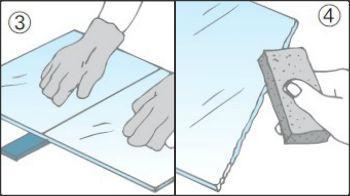

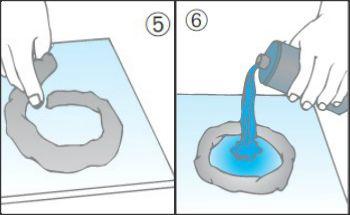

5) To pierce a sheet of glass perform around the area where the hole will be pierced, a small embankment of stucco.

6) Pour inside the embankment a certain amount of oil or trichlorethylene so that it forms a layer of a couple of millimeters. The substance will prevent breakage during the drilling phase.

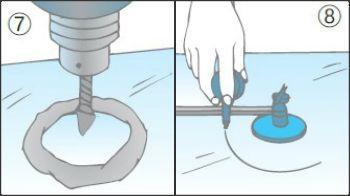

7) With a spearhead, specifically for glass and without pressing too much, practice hole.

8) To drill a large diameter hole use the compass glass cutter with a rotating arm fixed to a suction cup.

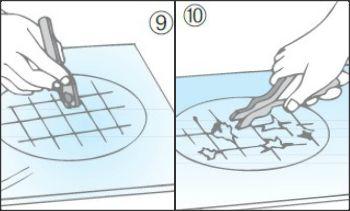

9) With a glasscutter perform some incisions arranged in a lattice on the part to be eliminated.

10) With any metal tool hit gradually the pieces of glass inside the area to be drilled and remove them with pliers.

The editors recommend:

Tools to drill the glass

The drilling of the glass is not particularly difficult, it requires a good deal of precision, but it also requires a specific tools and suitable to work this material as fragile as resistant. The purchase of specific products does not entail a great expense, and most of them can also be used on other fragile material, such as ceramics.

The first of the tools is the vetrographic pencil, which allows to score the glass and to delimit the profile of the cut. Its use is essential for precise work and it is a tool that you can easily find in a stationery store or in a paint shop at a very low price. The particular composition of the material allows a trace on the glass, without it being permanent and therefore allowing the correction of possible errors.

Inevitable, to continue operations, is the cutter wheel: this tool allows you to perform very precise cuts on a challenging material such as glass. A small wheel in stainless steel for maximum cutting precision. For large cuts, however, that require a more precise driving, you can use the compass cutters.

In this case the adjustable arm will enable a precise cut and perfectly circular, suitable, for example, for the installation of air vents that can fit properly into the opening. The compass cutter is a professional tool that guarantees excellent results and pinpoint accuracy.

However, also in this case the costs are usually contained, for a purchase that is worth to perform even if it is not expected to use it very often.

Another important tool for this type of operations is the spearhead: also in this case, the movement will be free hand, therefore it is important first to sketch in a precise way, with a vetrographic pencil, the profile to be followed to perform the cutting.

The spearheads can be purchased with different diameter of the tip, in order to intervene in a precise and appropriate way depending on the size of the glass and the type of cut to be performed.

The carborundum stone, cited above, is a not essential tool, but very useful for the better cleaning of the glass to be executed after the cut. The carborundum, or silicon carbide, an abrasive material is able to make the cut surface smooth, without causing fracture of the glass.

It is therefore a precision instrument which is needed to refine the work. The tool is usually characterized by a slight camber, right for an easy machining of curved surfaces.

80308 REGISTERED USERS