Wall of glass blocks: implementation

Post from EditorialsWall of glass blocks: illustrations of the construction phases of decorative partitions to enable the free division between spaces, spreading natural light.

A glass brick wall separates and diffuses light

Luminous wall: to divide a room or create a corridor between the functional night and day areas without shaping at all of the sharp separations that prevent natural lighting, you can create the characteristic and bright glass block partitions.

It is walls made of glazed tiles, called glass blocks or diffusers, precisely because of their inherent peculiarity of letting the light through between the spaces, also magnifying the global luminous effect thanks to the luminescent reflections on the iridescent and colored surfaces.

In the drawing, I drew a portion of the cylindrical stairwell connection between the living room and the underlying basement room, in the context of my project of redistribution of the spaces in a two floors villa.

Four rows of blue colored glass bricks outline a curved section solid vertical transparency; in this way it is possible to spread the natural light coming from the large window - identified on the left of the representation - towards the stairwell, creating a decorative dimension for this furnishing corner in the living area.

Some shelves in cherry wood follow the curves of the wall, setting up an architectural sinuous optical interconnect between environments.

Pose of the first glass blocks in the support frame

The glass blocks partitions do not in themselves constitute the self-supporting structures; accordingly, it is essential a rigid wooden frame fixed on the floor, the walls and the ceiling, so as to form a sturdy large supporting frame for the glass blocks.

The wall of glass blocks should not exceed 6 meters in length and can not have a surface of more than 18 square meters or so, because it would be missing the conditions for a strong safety of the structure in its entirety; to carry out works of higher amplitude, there must be intermediate uprights, to design custom-made case by case.

To determine the internal dimensions of the supporting frame, it is placed on the floor a row of glass blocks, including the intermediate and terminal spacers, thereby measuring the overall required length; in the same way it is done the calculation of the height of the support frame.

The frame is usually built in wood, with a thickness of 5 cm, with special attention so that is perfectly squarely aligned; only then it can be secured by means of screws, to the floor and to the pre-existing walls.

Before getting started, cut the special plastic spacers so that you can then enter them into the intermediate and terminal junctions between the diffusers and the wooden frame.

A specific rubber band is fastened to the uprights of the frame, to create the right friction during assembly.

Once mixed the mortar, ispread a layer of it on the frame base.

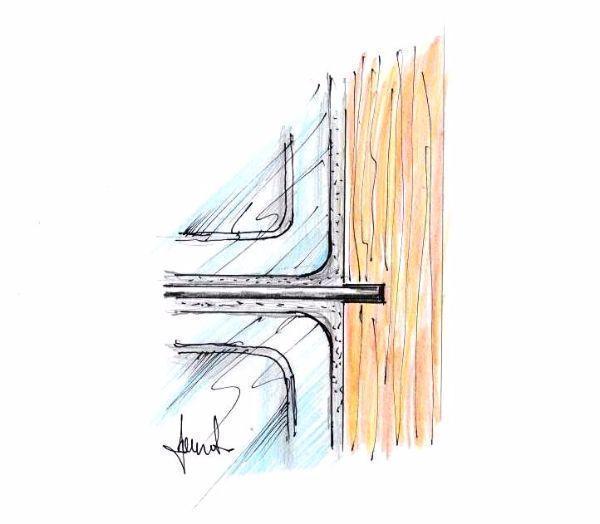

Starting from a corner, place an L-shaped spacer and place the first glass block, stopped on its other edge by a T-shaped as is clear from the above illustration.

Construction of glass block partition wall with steel reinforcement bars

Continue lying the mortar on the vertical side of the next diffuser, so as to fill the transition side concavity; then it is placed precisely next to the previous glass block, by including another T-shaped spacer.

To confer structural strength to the partition wall, should be inserted metal rods, in steel or galvanized iron, both horizontally and vertically within the thickness of the layers of mortar, so as to constitute a solid network of reinforcement for the entire wall in construction.

One proceeds exactly the same way for each layer, placing the various rows of glass diffusers one above the other.

Holes for the rods in the frame of the glass blocks wall

As you lay the layers of glass blocks, in order to obtain a majority of the metal bracing drowned in the mortar, it is necessary to drill holes in the wooden frame where can be inserted the ends of the rods.

To even out the mortar that goes out, use a spatula to equalize the joints between the glass blocks.

Turn the side plates of the spacers in the joints, removing them with a move to release; It will be taken off the excess mortar from the joints, using a damp sponge.

Once the cement binder has set, it must make the surface smooth by passing along the joints a wooden stick.

Only when the mortar is completely dry, you can clean and polish the concrete and glass diffusers.

Therefore, after deciding the shape and positioning of the new wall with a careful preparation, you can then build a partition wall of glass blocks that can divide the space with a surplus of natural light.

Our online service for freehand design allows everyone to give shape to unique solutions for the division of internal and external environments, responding to the multiple housing needs, to expertly combine design and functionality.

80276 REGISTERED USERS